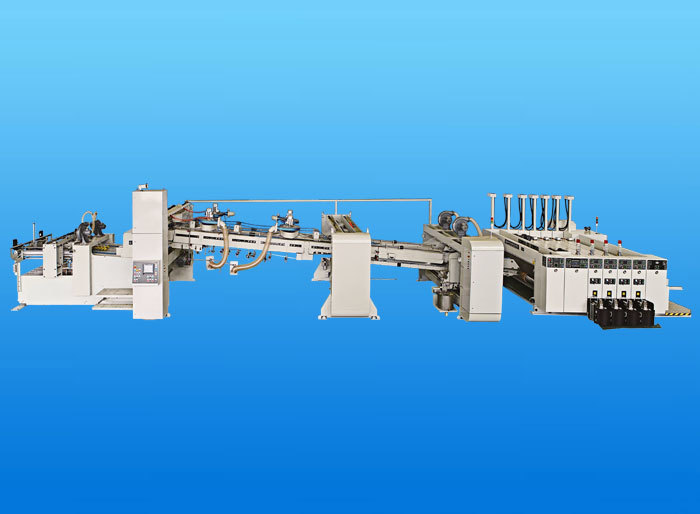

WAM3000 Series Fully Automatic Water-Based Printing Slotting Die-Cutting Machine

Specializing in corrugated cardboard printing slotting machine, printing slotting folding paste box linkage line and other corrugated box equipment, as well as special fiber heat treatment machine, spinning dryer, washing machine, multi-roller tractor and other chemical fiber equipment.

Key words:

WAM3000 Series Fully Automatic Water-Based Printing Slotting Die-Cutting Machine

Product Details

WAM3000 Series Fully Automatic Water-Based Printing Slotting Die-Cutting Machine

Functions and Features

1. The whole machine is designed and manufactured according to reliability and safety, with quick order change and easy operation.

2. Selected high-quality materials and components, hardened drive gears, made of high-quality alloy steel.

3. Uses keyless connection to reduce center wear and maintain long-term printing registration.

4. All rollers are chrome-plated and corrosion-resistant, enhancing hardness.

5. Uses a centralized automatic lubrication oil pump to maintain the mechanical life of machine parts.

6. Can feed paper continuously or sheet by sheet, with the machine counter accurately recording production quantity.

7. Full vacuum transfer system.

8. Closed ink scraper system can improve the printing quality of the machine.

9. Quick drying device. (Optional)

10. Uses PLC and touch screen multifunction control, can store orders.

11. Equipped with machine zeroing and plate cleaning memory recovery function, can automatically return to the original position, shortening adjustment time.

12. Automatic zeroing and automatic reset.

|

Parameter Name |

Unit |

Model |

|

|

WAM3000-1120 |

WAM3000-1122 |

||

|

Maximum Paper Size (W×L) |

mm |

1050×2000 |

1050×2200 |

|

Maximum Printing Size (W×L) |

mm |

1050×1800 |

1050×2000 |

|

Minimum Paper Size (W×L) |

mm |

300×520 |

300×520 |

|

Applicable Cardboard Thickness |

mm |

3-9 |

3-9 |

|

Standard Plate Thickness |

mm |

7.2 |

7.2 |

|

Printing Roller Axial Displacement |

mm |

10 |

10 |

|

Registration Accuracy |

mm |

±0.5 |

±0.5 |

|

Maximum Mechanical Speed |

pcs/min |

200 |

200 |

Specializing in corrugated cardboard printing slotting machine, printing slotting folding paste box linkage line and other corrugated box equipment, as well as special fiber heat treatment machine, spinning dryer, washing machine, multi-roller tractor and other chemical fiber equipment.

Enterprise strength:

The company has more than a dozen technical research and development teams and dozens of processing and manufacturing equipment. After more than 20 years of work accumulation, the company has successively cooperated with international advanced technology brands such as Bosch Rexroth (BOSCH REXROTH) in Germany and Meigu (UMETANI) in Japan. The corrugated box equipment produced has been exported to more than 30 countries and regions in the world, winning praise from customers at home and abroad. In recent years, the company has set up a special fiber chemical fiber equipment division, and has carried out technical exchanges and equipment manufacturing and sales cooperation with foreign companies such as Japan Concorde (KYOWA FINE TECH), Japan Takeda (TAKEDA WORKS), Kawasaki Heavy Industries (KAWASAKI) and Japan Special Electric (TOKUDEN). The products are sold to Japan, South Korea, Southeast Asia and other countries.

Related Products